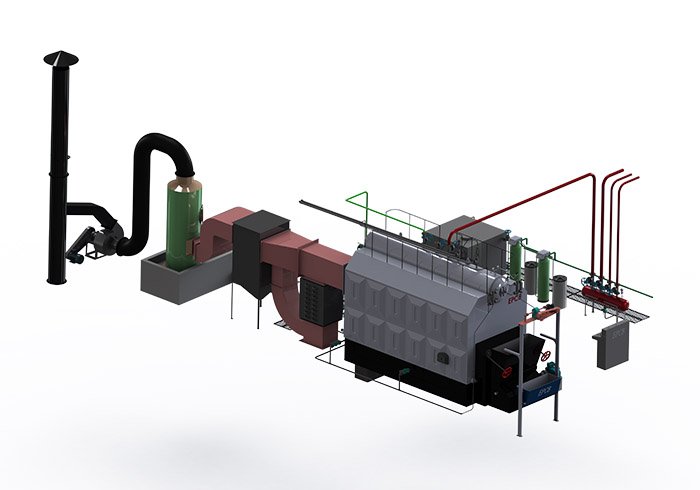

As an important way of traditional energy utilization, coal-fired boilers occupy an irreplaceable position in industrial production, heating and power generation. With the increasing emphasis on environmental protection and energy efficiency, how to effectively manage coal-fired boilers has become an urgent issue.

In the operation of coal-fired boilers, slag removal is a link that cannot be ignored. With the combustion of fuel, the boiler will produce a large number of ash and coke slag, if not removed in time, will affect the normal operation of the boiler, and even cause equipment damage and safety accidents. Therefore, the selection and use of slag remover is crucial.

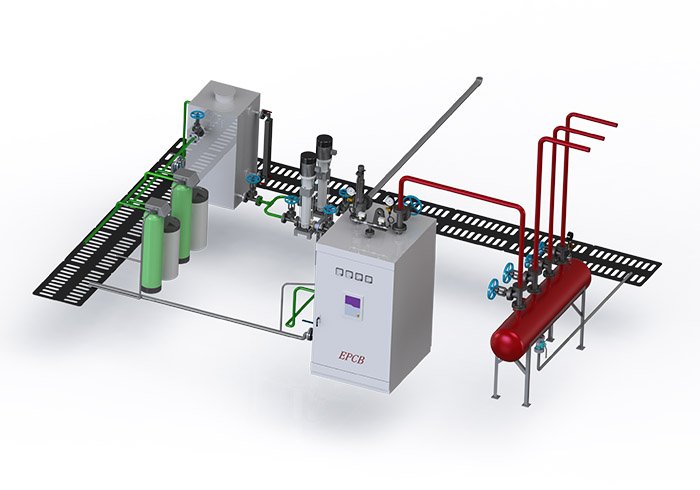

As a well-known boiler manufacturer in China, EPCB boiler combined with decades of experience in customer selection, summarized that different types of slag removers have different working principles and characteristics, of which the scraper type and spiral slag removers are two common choices.

What are Scraper Slag Removers and Spiral Slag Removers?

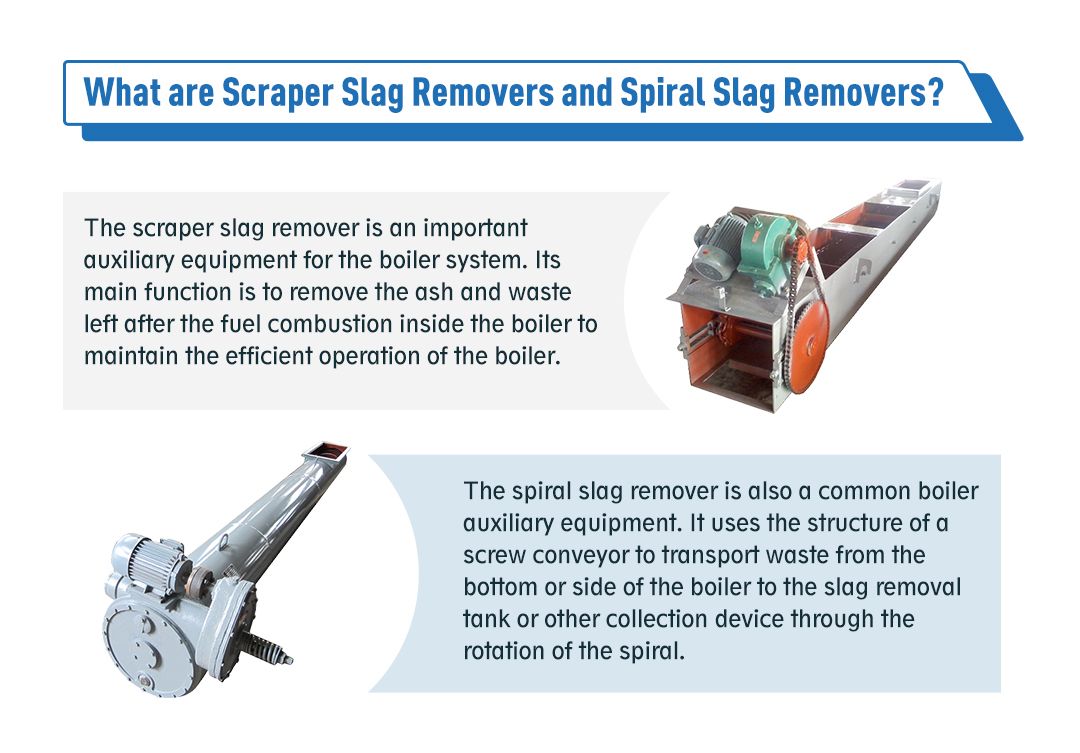

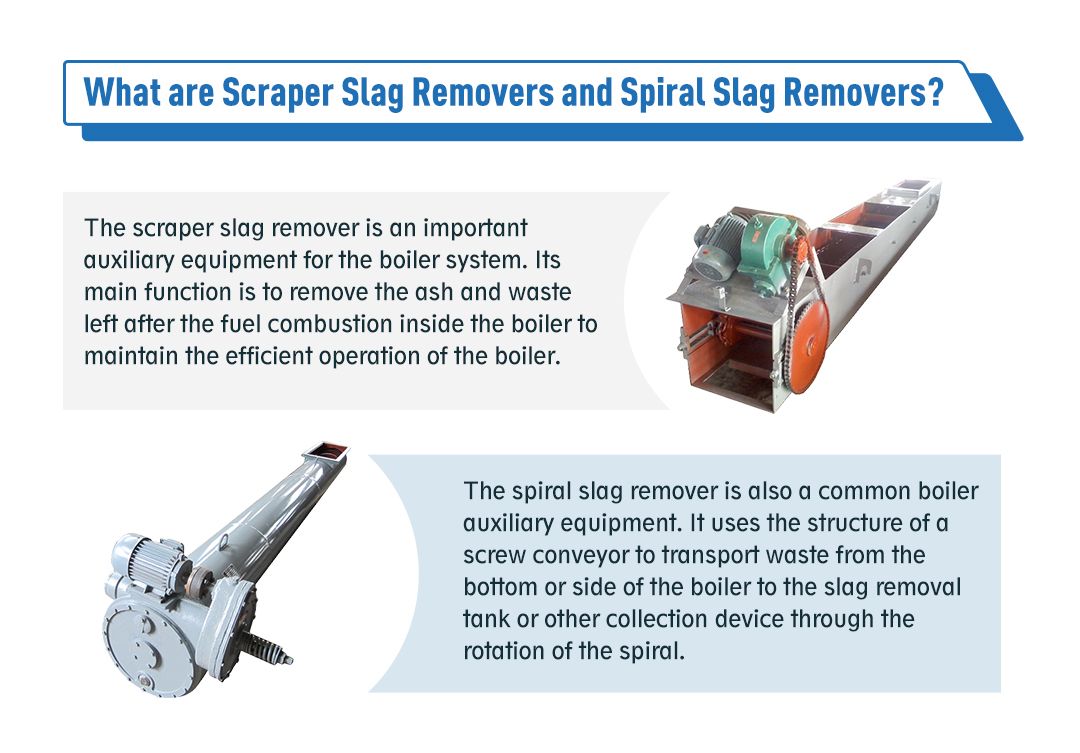

1.Scraper Slag Remover

Scraper slag remover is a kind of important auxiliary equipment used in boiler system, its main function is to remove the ash and waste left after fuel combustion inside the boiler and keep the boiler running efficiently.

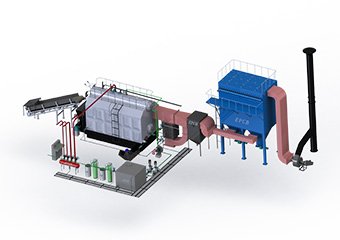

It usually consists of scraper/chain, slag removing chute, conveyor belt, driving system, control system, etc. It is installed at the bottom or side of the furnace chamber of the boiler. The working principle of scraper slag remover is similar to manual cleaning, but it operates faster and more efficiently to remove the slag inside the boiler in a timely and effective manner.

Scraper slag remover adopts mechanical scraper to effectively remove the ash and waste inside the boiler and remove the slag into the slag hopper. It has the advantages of simple operation, stable structure, good removal effect, etc. It is suitable for some demanding environments, such as boilers under high temperature and high pressure.

2.Spiral Slag Remover

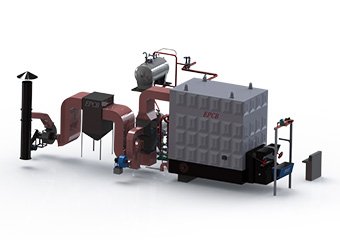

Spiral slag remover is also a common boiler auxiliary equipment for removing ash and waste produced by combustion inside the boiler. It utilizes a screw conveyor structure, which conveys waste from the bottom or sides of the boiler to a deslagging tank or other collection device by means of the rotary motion of a screw.

It usually consists of screw conveyor (screw shaft), driving device, supporting frame, slag removing tank (or collecting device), control system and so on, and is installed at the bottom or side of the boiler's furnace. The working principle of Spiral slag remover is similar to that of screw conveyor, and its advantages lie in its simple structure and stable operation, which is suitable for some environments requiring continuous operation.

In the boiler system, both scraper type and Spiral type slag remover play an important role in removing slag. With the combustion process, the boiler will continuously produce ash and cinders, if not removed in time, it will affect the normal operation of the boiler, and even lead to equipment damage and safety accidents. The task of scraper and Spiral slag remover is to remove these slags timely and effectively to ensure the safe and stable operation of the boiler system.

Therefore, when choosing a scraper-type or Spiral-type slag remover, it is necessary to consider the specific conditions of the boiler system, such as the operating environment, the amount of slag produced, the skill level of the operator and other factors. Reasonable selection and use of slag remover will help to improve the operating efficiency of the boiler system, extend the service life of the equipment, reduce maintenance costs, so as to maximize the use of energy and environmental protection goals.

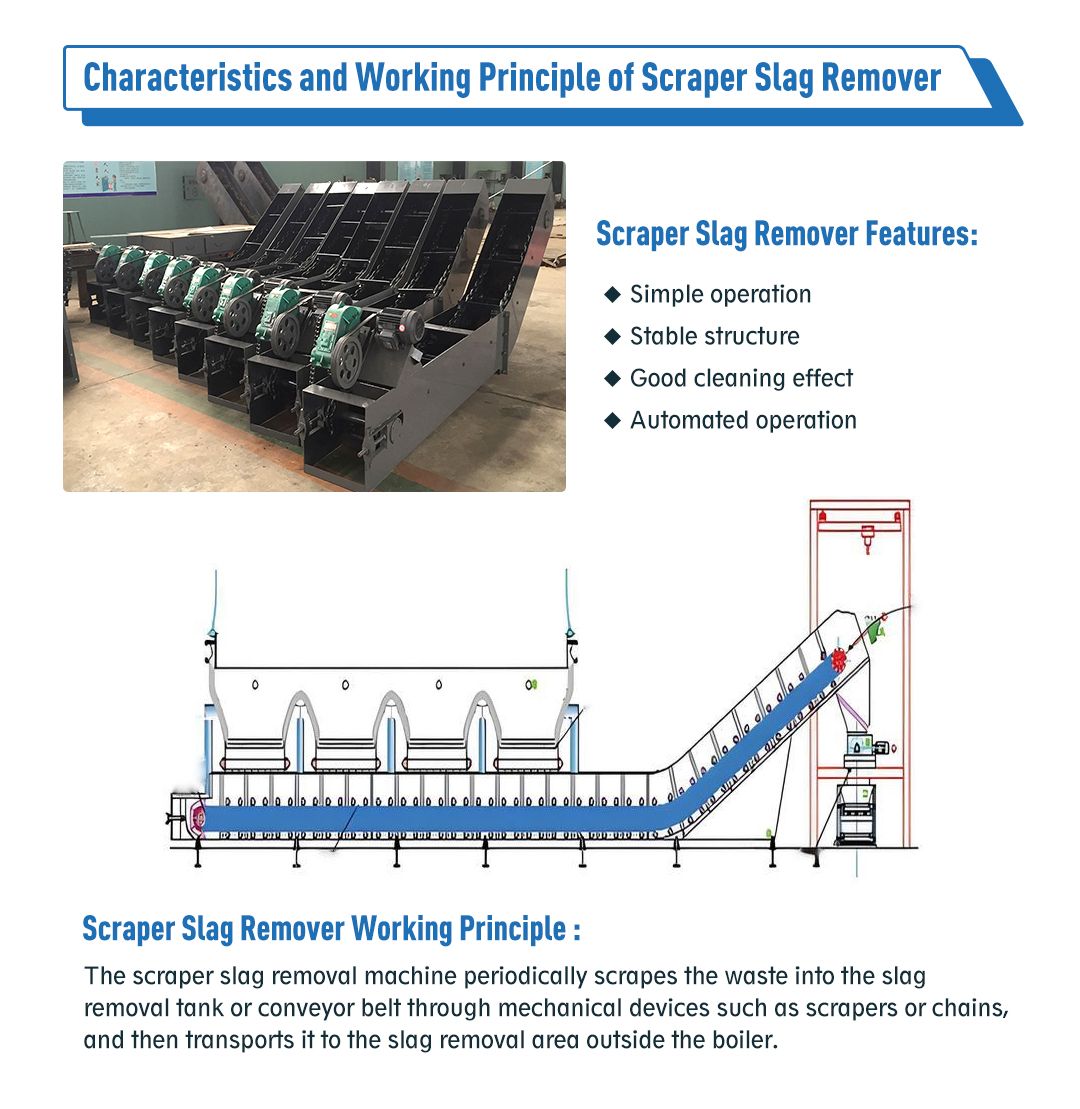

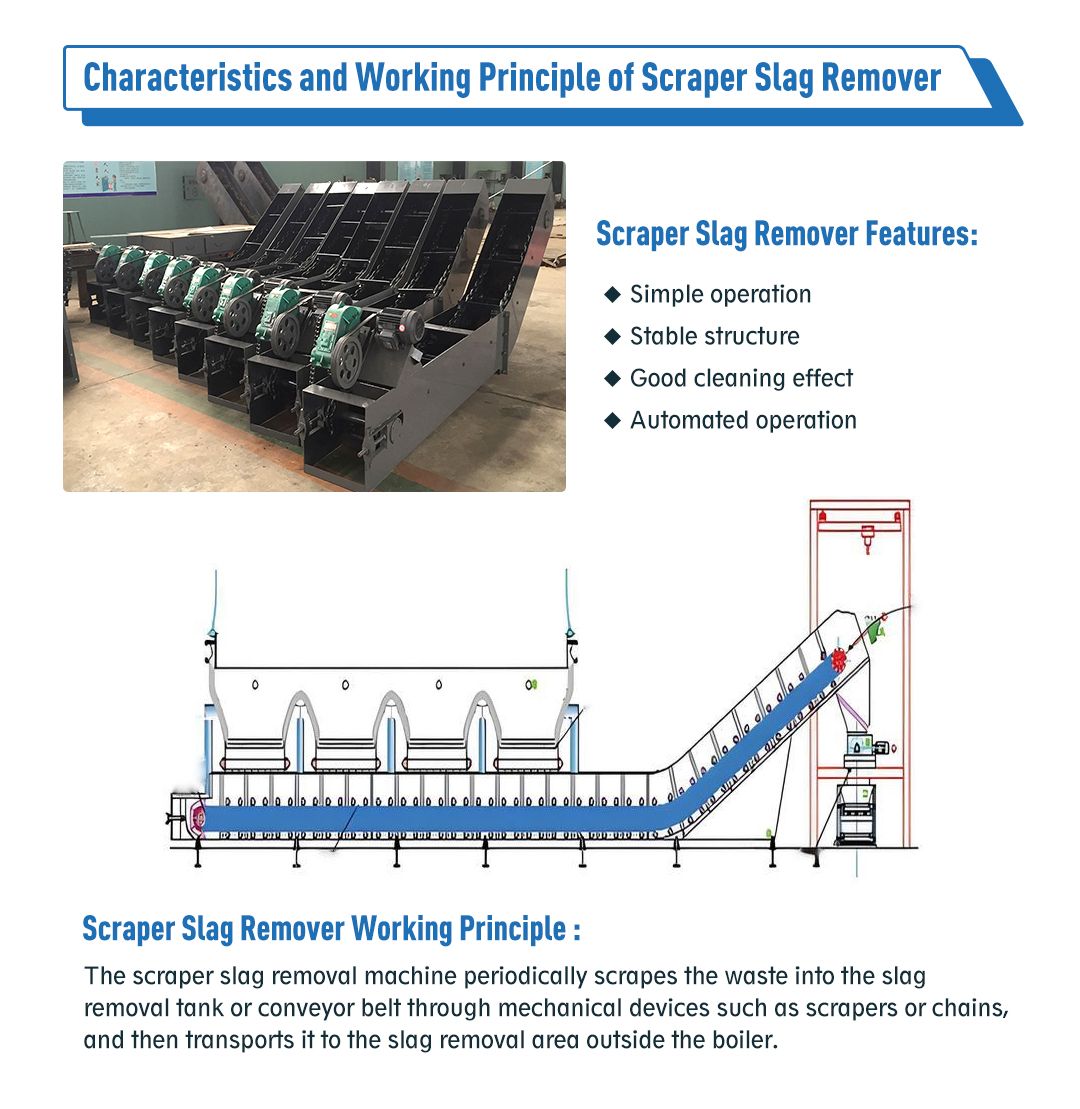

Features and Working Principle of Scraper Slag Remover

Understanding the characteristics and working principle of the scraper slag remover is of great significance for the normal operation of the boiler system, safe production, energy saving and emission reduction.

Features of Scraper Slag Remover:

Simple operation: Scraper slag remover usually uses mechanical scraper to remove, the operation is relatively simple, do not need too much professional skills.

Structural stability: the structure of the scraper slag remover is relatively stable, with long service life and low maintenance cost.

Good removal effect: It can effectively remove ash and waste inside the boiler and keep the inside of the boiler clean.

Automated operation: Equipped with an automated control system, it is able to carry out scraping operations autonomously as needed, reducing manual intervention.

Scraper Slag Remover Working Principle:

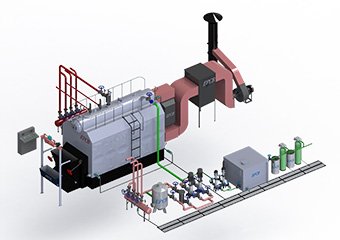

During operation, when the fuel inside the boiler is burned, the scraper slag remover leaves ash and waste deposited at the bottom of the boiler. The scraper type deslagging machine will periodically scrape the wastes into the deslagging chute or conveyor belt by means of a mechanical device such as a scraper or chain, and then transport them to the deslagging area outside the boiler. Modern scraper de-slaggers are usually equipped with an automated control system that automatically triggers the scraping operation based on boiler operating conditions and slag thickness to ensure timely and efficient waste removal.

In the process of coal-fired boiler slag removal, scraper slag remover has better applicability. First of all, due to the simple operation of the scraper slag remover, does not require too much professional skills, so it is suitable for all kinds of boiler systems, including industrial production, heating and power generation fields. Secondly, the scraper slag remover has good removing effect, which can timely and effectively remove the slag inside the boiler and ensure the safe and stable operation of the boiler. Furthermore, the scraper slag remover has a stable structure, long service life and low maintenance cost, which is suitable for long-term operation of industrial and energy facilities.

In the field of industry and energy, scraper type slag remover is widely used in all kinds of coal-fired boiler systems. For example, steam boilers in industrial production, hot water boilers in heating systems, and power generation boilers in power plants need to be equipped with slag removing equipment, and the scraper slag remover, as an economical and practical choice, is often chosen for these application scenarios, to provide protection for the safe, stable, and efficient operation of the boiler system.

Precautions:

Regular Maintenance: Regular inspection and maintenance of scraper, chain, drive system and other components are needed to ensure their normal operation.

Safe operation: Operators should operate in strict accordance with the operating procedures to ensure safety and avoid accidents caused by improper operation.

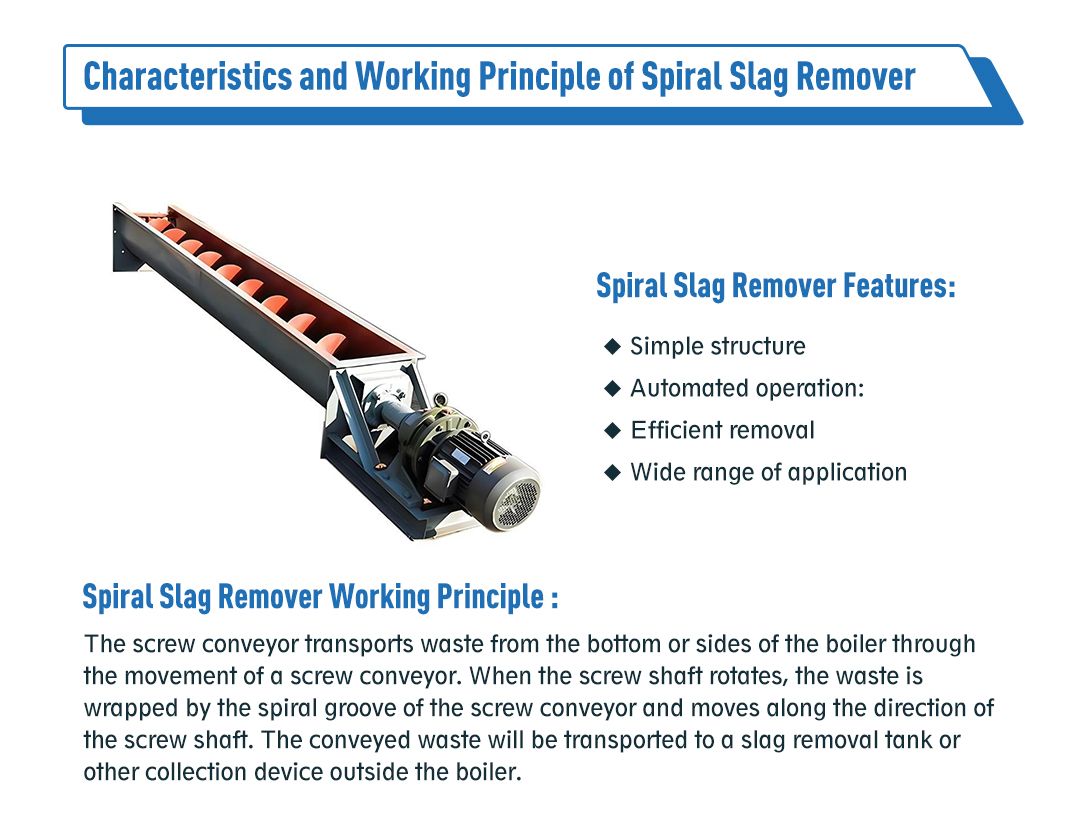

Characteristics and Working Principle of Spiral Slag Remover

As an important auxiliary equipment in the boiler system, the working condition of the spiral slag remover directly affects the operating efficiency and stability of the boiler. By understanding its characteristics and working principle, it can be targeted to optimize the boiler system, improve energy efficiency, reduce energy consumption and operating costs.

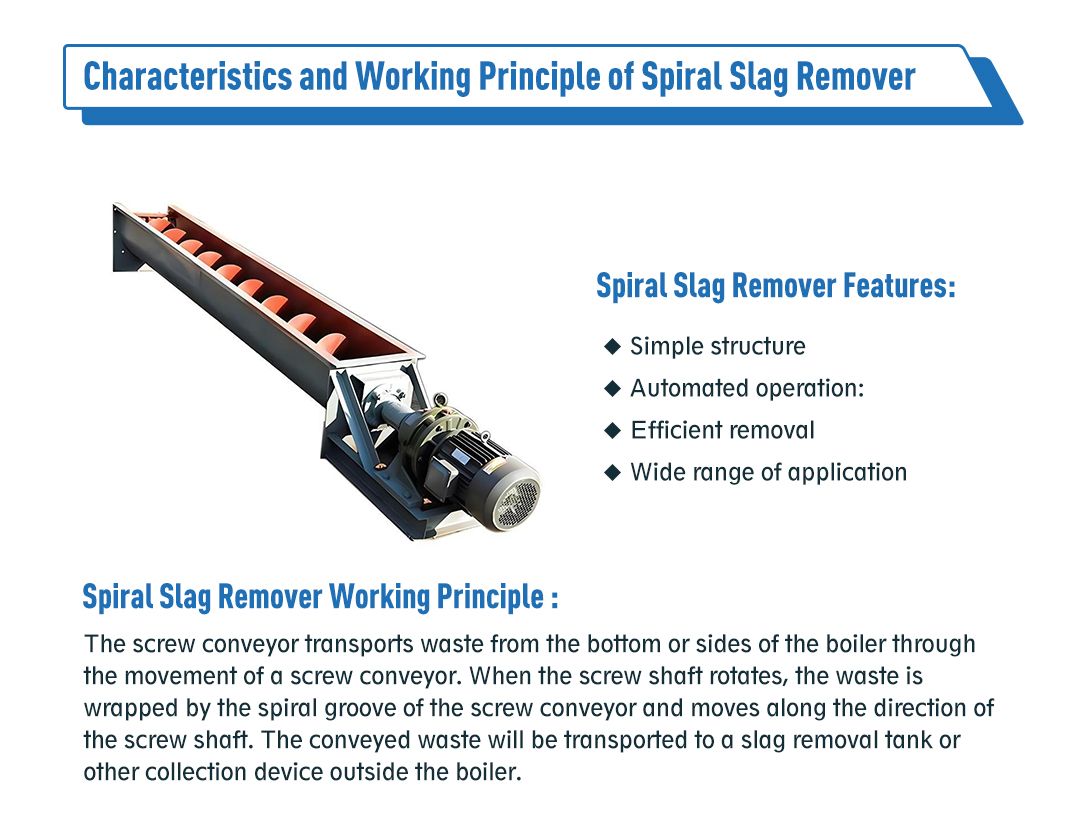

Spiral Slag Remover Features:

Simple structure: Spiral slag remover usually consists of screw conveyor, driving device and support frame, the structure is relatively simple, easy to install and maintain.

Automated operation: Equipped with an automated control system that automatically starts and stops the boiler according to its operating status and waste buildup, improving operational convenience and efficiency.

Efficient removal: The screw structure of the screw conveyor can efficiently transport the waste from the bottom or side of the boiler to the deslagging tank for better removal.

Wide range of application: applicable to various types of boilers, including coal-fired boilers, gas boilers, biomass boilers, etc.

Spiral Slag Remover Working Principle:

Spiral Slag Remover convey waste out of the bottom or side of the boiler by the movement of a screw conveyor. The screw conveyor usually consists of one or more screw shafts that are constructed in a spiral shape. As the screw shaft rotates, the waste is wrapped around the spiral grooves of the screw conveyor and moves in the direction of the screw shaft. The conveyed waste is then transported to a deslagging tank or other collection device outside the boiler. The deslagging chute is usually located at the end of the spiral deslagging machine and is used to collect the waste for further treatment or discharge.

Modern spiral slag removers are usually equipped with an automated control system. This control system monitors the operating status of the boiler and the accumulation of waste and automatically adjusts the operation of the screw conveyor as required.

Spiral slag removers have a wide range of applications in the industrial and energy sectors, including the following:

Thermal power plants: As an important part of coal-fired boiler system, spiral slag remover is widely used in thermal power plants to ensure the stable operation of boiler system.

Industrial boiler: The boiler system in the industrial production process also needs to remove slag, and the spiral slag remover can meet the slag removal needs of industrial boilers.

Boiler Retrofit Projects: When retrofitting and upgrading boiler systems that have been in operation for some time, spiral slag removers are often introduced to improve the cleanliness and efficiency of the system.

Energy recovery projects: Spiral slag remover can also be used in some energy recovery projects, such as the use of waste heat power generation, etc., to remove the waste slag produced by the boiler system and improve the efficiency of energy utilization.

Comparison of the performance characteristics of scraper and spiral slag remover

Scraper slag remover and spiral slag remover are two common types of coal-fired boiler slag removal equipment, and they have some obvious differences in performance characteristics:

Performance Characteristics of Scraper Slag Remover:

Mechanical structure is simple: scraper slag remover is composed of scraper and pusher, the structure is relatively simple.

Slag removal efficiency is low: scraper slag remover in the removal of slag, scraper needs to be pushed through the pusher to push the slag to the slag outlet, the removal of low efficiency, especially for the thicker layer of slag effect is not good.

Relatively easy to operate and maintain: due to the simple structure, the operation and maintenance of the scraper type slag remover is relatively easy.

Performance characteristics of Spiral Slag Remover:

High removal efficiency: spiral slag remover adopts screw conveyor, which can continuously convey the slag to the slag discharge port, with high removal efficiency, especially suitable for thicker slag layer.

High degree of automation: usually used in conjunction with automatic control systems to realize automatic control, reduce manual intervention and improve work efficiency.

Strong adaptability: The spiral slag remover is suitable for all types of coal-fired boiler systems with stable work and strong adaptability.

They each have advantages and disadvantages in different coal-fired boiler systems:

For smaller or simpler coal-fired boiler systems, scraper slag removers may be more suitable because of their simple construction, relatively easy operation and maintenance, and relatively low cost.

For large or complex coal-fired boiler systems, spiral slag removers are more advantageous. Due to its high removal efficiency, continuous operation and high degree of automation, it can better meet the removal needs of large-scale coal-fired boiler systems and improve the stability and efficiency of the system. Especially in the treatment of thick slag layer or high temperature and high pressure conditions, the spiral slag remover performance is more outstanding.

In summary, the choice of scraper slag remover or spiral slag remover should be based on the size of the specific coal-fired boiler system, the operating conditions, and the removal requirements.

Scenarios and Environments For Different Slag Removers

The applicability of scraper type and spiral type slag remover in different environments and working conditions can be analyzed according to their characteristics.

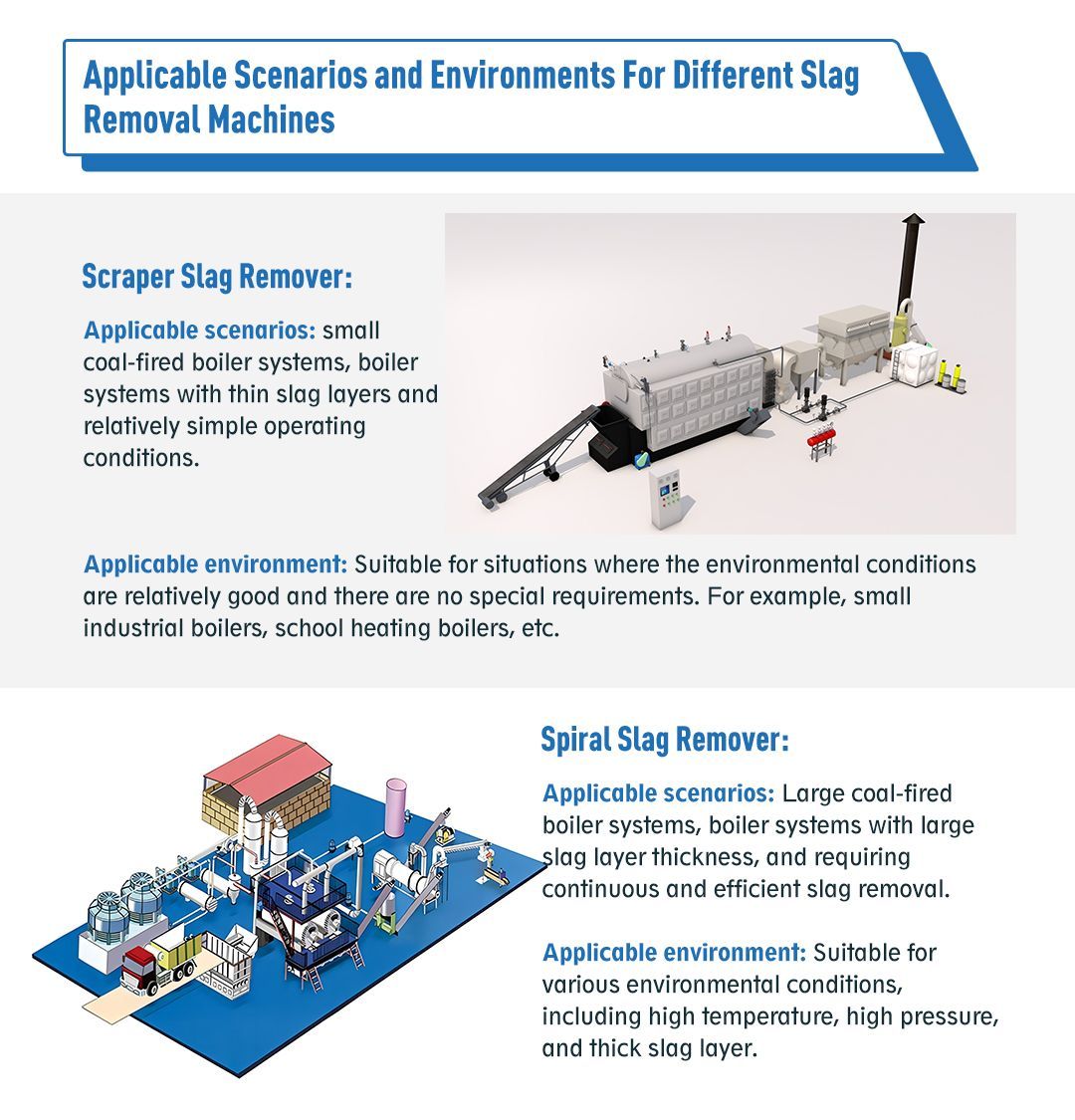

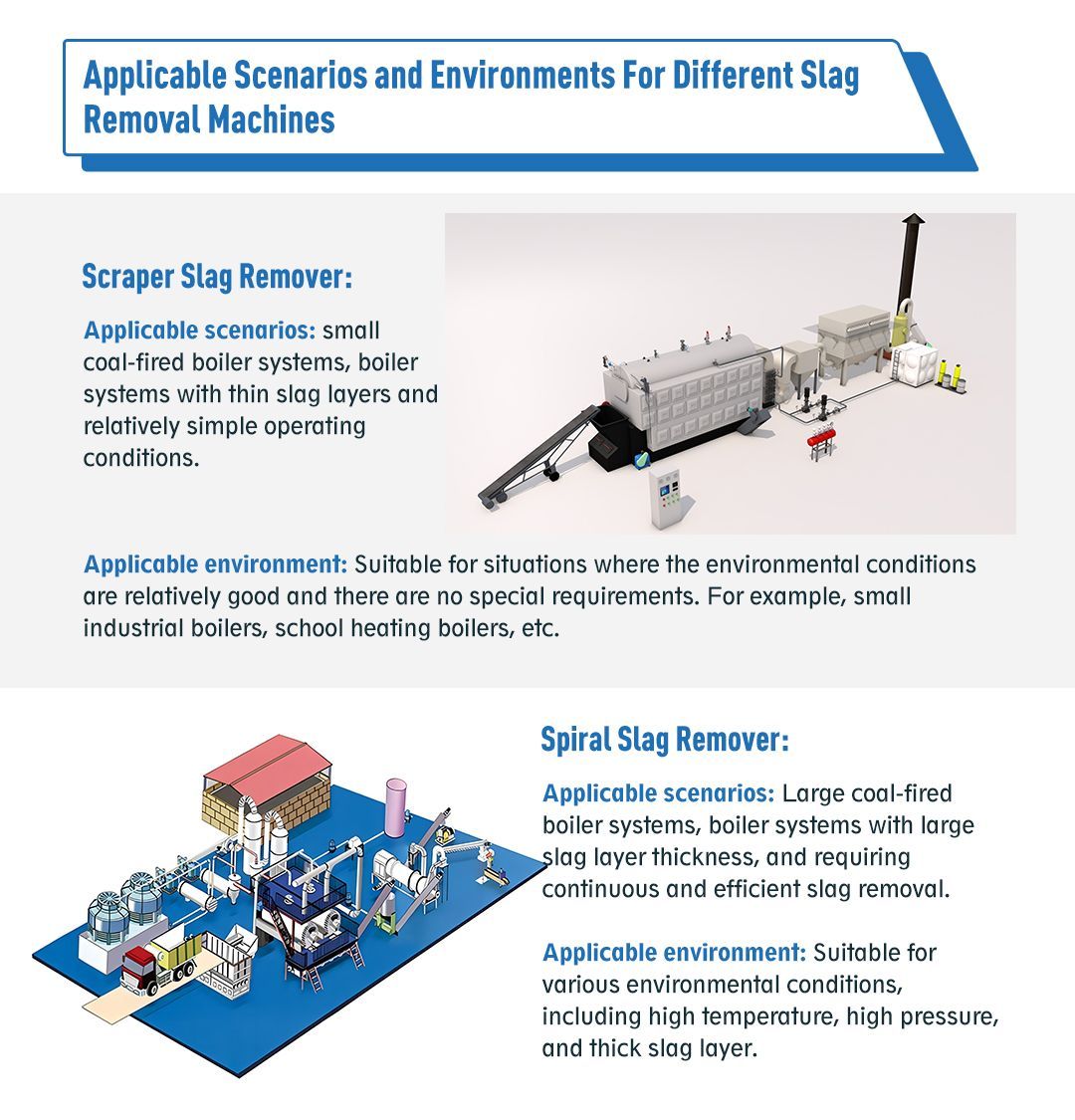

Applicable scenes and environments of scraper slag remover:

Applicable scenes: small coal-fired boiler systems, boiler systems with thin slag layers and relatively simple operating conditions.

Applicable environment: Due to the simple structure and convenient operation of the scraper type slag remover, it is suitable for relatively good environmental conditions and no special requirements. For example, small industrial boilers, school heating boilers and so on.

Some small rural areas or school heating boiler systems, due to the small size and relatively simple operating conditions, usually use the scraper type slag remover for slag layer removal to meet the basic slag removal needs.

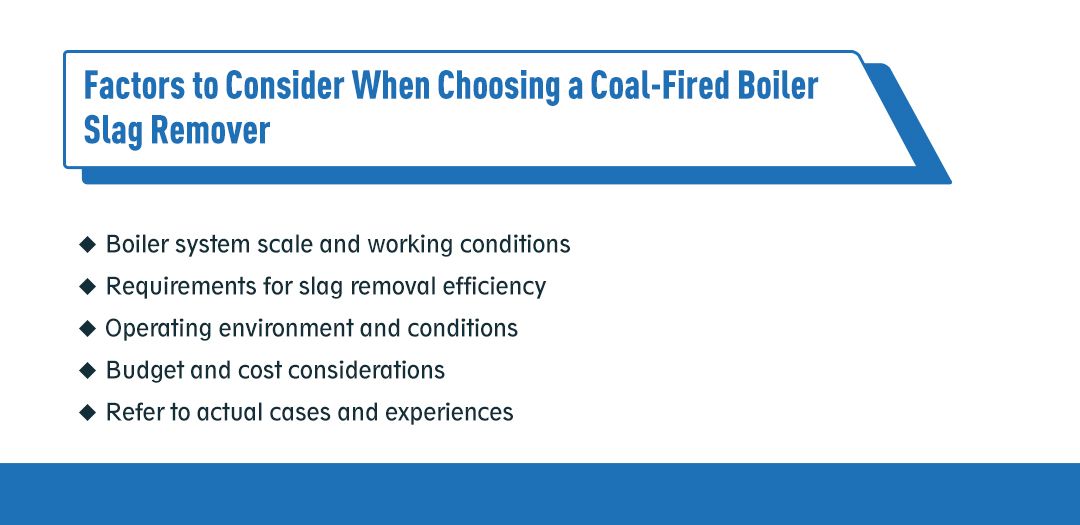

Scenarios and environments of Spiral slag remover:

Applicable scenes: large coal-fired boiler system, slag layer thickness is large, the need for continuous and efficient removal of slag boiler system.

Applicable environment: Due to the high removal efficiency and adaptability of the spiral slag remover, it is suitable for a variety of environmental conditions, including high temperature and high pressure, slag layer thickness.

Large thermal power plants are typical application scenarios for spiral slag removers. For example, the boiler systems of some large-scale thermal power generation groups in China usually use spiral slag removers for efficient and continuous slag removal to ensure stable boiler operation.

In general, scraper slag removers are suitable for small and simple coal-fired boiler systems, while spiral slag removers are more suitable for large and complex coal-fired boiler systems, especially when efficient and continuous slag removal is required. Choosing the right slag remover should be considered in light of the specific boiler system characteristics and operational needs.

Coal-Fired Boiler Slag Remover Selection Guide

When selecting a slag remover for a coal-fired boiler, we need to carefully consider the needs and conditions of the particular coal-fired boiler system. Correctly selecting the right slag remover can improve the stability and efficiency of the boiler system, prolong the service life of the equipment and reduce the operating costs, thus ensuring the reliability and continuous operation of the whole system.EPCB Boiler, as a professional boiler manufacturer, we suggest the following guidelines, which are dedicated to helping our customers to provide the boiler equipment that is most suitable for their needs.

1.Boiler system size and operating conditions:

In the case of small or medium-sized coal-fired boiler systems with relatively simple operating conditions and thin slag layers, a scraper slag remover is usually more suitable.

For larger coal-fired boiler systems with thicker slag layers, such as large thermal power plants, spiral slag removers are more suitable because they can efficiently remove thick slag layers and can realize continuous operation to improve slag removal efficiency.

2.Slag removal efficiency needs:

If the boiler system does not require high slag removal efficiency and the slag layer is relatively thin, the scraper slag remover can meet the basic needs and the cost is relatively low.

If high efficiency and continuous slag removal is required, and if boiler operational stability is a high priority, a spiral slag remover should be selected, which offers higher removal efficiency and is more adaptable.

3.Operating environment and conditions:

Consider whether the boiler is operating in a harsh environment, such as high temperature and high pressure conditions, and whether automated control is required. Screw slag removers are more stable and reliable in these environments and often have a higher degree of automation.

If the environmental conditions are relatively good and the operation is simple, the scraper type slag remover can also be considered, which is relatively easy to maintain and operate.

4.Budget and cost considerations:

Scraper Slag Removers are usually less costly and are suitable for those on a limited budget.

Spiral Slag Removers are usually more expensive, but can provide longer term benefits where large, efficient, continuous scum removal is required.

5.Refer to actual cases and experiences:

Consider consulting with industry experts or other users of similar coal-fired boiler systems to learn about their choices and experiences with them, which can help you make a more informed decision.

Conclusion

Through the above content, we fully understand about the characteristics and performance of scraper slag remover and spiral slag remover, I believe you will have a certain understanding of the selection of slag remover, you can according to the specific needs of coal-fired boiler system, working conditions, budget and environmental conditions, combined with the characteristics and performance of the scraper and spiral slag remover to make a comprehensive consideration, to choose the most suitable slag remover model, in order to ensure that the boiler system's stable The most suitable model of slag remover is selected to ensure the stable operation and clean slag discharge of the boiler system.

If you have other questions about slag remover and boiler selection, welcome to consult EPCB boiler, we will be happy to serve you.

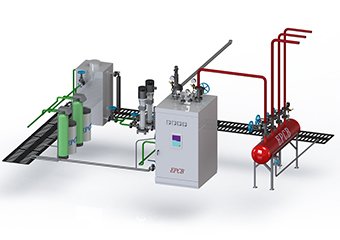

Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Hot Water Boiler

Hot Water Boiler